GLASS REINFORCED ACRYLONITRILE

BUTADIENE STYRENE (ABS-GF)

Glass Reinforced ABS (ABS-GF)

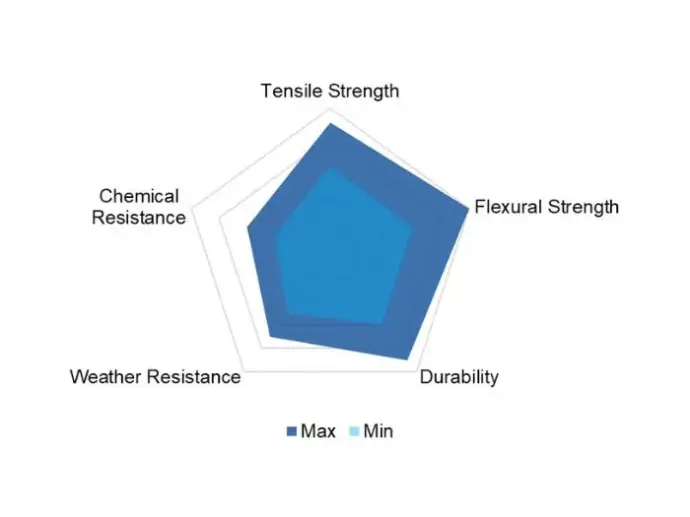

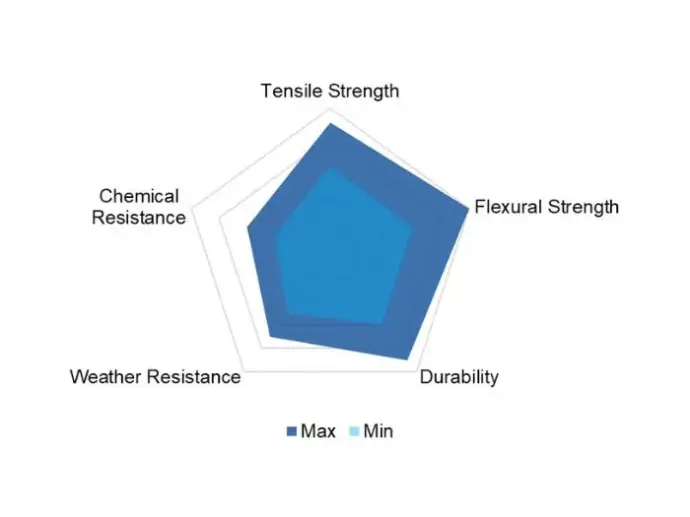

ABS-GF compounds in 3D printing combine the inherent strength and impact resistance of ABS with the added reinforcement of glass fibres. This composite material offers improved mechanical properties, including enhanced tensile strength and stiffness, making it suitable for applications where increased structural integrity is essential. The glass reinforcement in ABS compounds enhances the material's dimensional stability and resistance to wear, contributing to its versatility in 3D printing.

Glass Reinforced Acrylonitrile Butadiene Styrene (ABS-GF) compounds in 3D printing combine the inherent strength and impact resistance of ABS with the added reinforcement of glass fibres. This composite material offers improved mechanical properties, including enhanced tensile strength and stiffness, making it suitable for applications where increased structural integrity is essential. The glass reinforcement in ABS compounds enhances the material's dimensional stability and resistance to wear, contributing to its versatility in 3D printing.

GLASS REINFORCED ABS (ABS-GF) PRODUCTS

GLASS REINFORCED ACRYLONITRILE BUTADIENE STYRENE PRODUCTS

Greatly improved mechanical properties

Good durability

Suitable for injection moulding, extrusion, and additive manufacturing

• Greatly improved mechanical properties

• Good durability

• Suitable for injection moulding, extrusion, and additive manufacturing